No Products in the Cart

Moisture density gauges, also known as nuclear densometers, are instruments used to measure the moisture content and density of soil, asphalt, and other construction materials. These gauges are commonly used in the construction industry to determine the compaction level of the soil or material being tested.

Moisture density gauges work is by using a radioactive source, typically cesium-137 or americium-241, to emit gamma rays into the material being tested. These gamma rays penetrate the material and interact with the atoms in it, causing them to emit secondary radiation, which is then detected by the gauge. By measuring the intensity of the secondary radiation, the gauge can determine the density of the material.

In addition to measuring density, moisture density gauges can also measure the moisture content of the material being tested. This is achieved by using a second radioactive source, typically americium-241, to emit neutrons into the material. These fast neutrons are emitted into the material being tested, and are scattered by the atoms within that material, some of which reflect back to the detector. The H3 tube is capable of detecting only those neutrons which have been thermalized (slowed down). Since hydrogen is the most effective element in the universe at thermalizing neutrons, the theory is that the more H2O present in the material, the more detections occur. Unlike density, where more detections indicate lesser densities, more detections by the moisture system indicates proportionately higher levels of moisture.

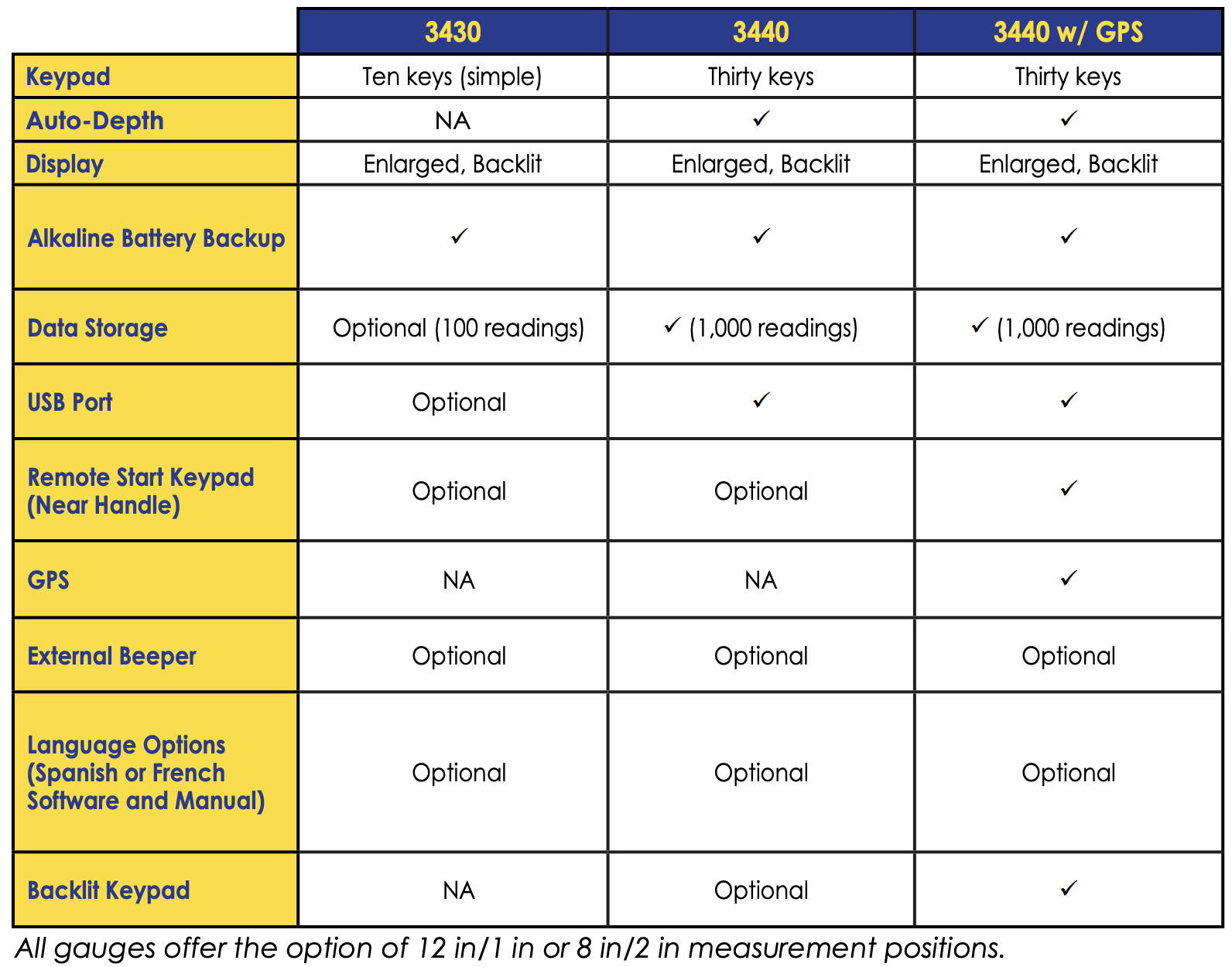

Many contractors, engineers, and highway departments use Troxler nuclear moisture density gauges to control the compaction of various materials such as soil, aggregate, concrete, and full-depth asphalt. To measure the density of a particular layer, the operator selects either the backscatter or direct transmission mode, depending on the material type and the layer's thickness. Troxler offers two models of nuclear moisture density gauges the model 3430 and 3440, which the differences between these can be found below.

The Model 3430, is the most basic and cost-effective option while the Model 3440 features a larger keypad and additional features suitable for certain construction projects. Both models meet or exceed the standards set by ASTM, including D6938, D2950, and C1040, and can be customized according to your testing requirements. Below is a graphic that compares the two top moisture density gauges on the market.

For more information about the features of the Troxler 3430 and 3440, please click here

The Troxler 3430 features Moisture Measurement

Moisture content is measured non-destructively using a test mode that detects thermalized neutrons. These neutrons are slowed down by the hydrogen present in the material, typically in the form of water, allowing for the determination of moisture levels.

The Troxler 3440 Features Backscatter Measurement & Direct Transmission Measurement

Backscatter Measurement

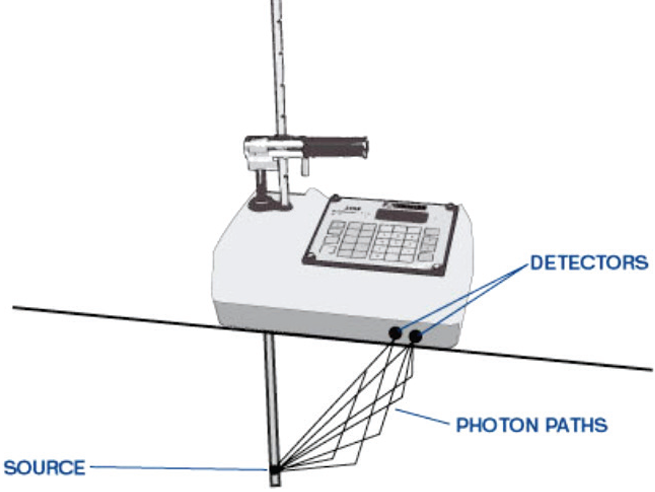

This is a fast and non-destructive method used to test materials, primarily asphalt and concrete, that are about 4 inches (10 cm) deep. The gauge's gamma source remains internal, and the density of the material is determined by counting the gamma rays that are scattered back toward the detectors.

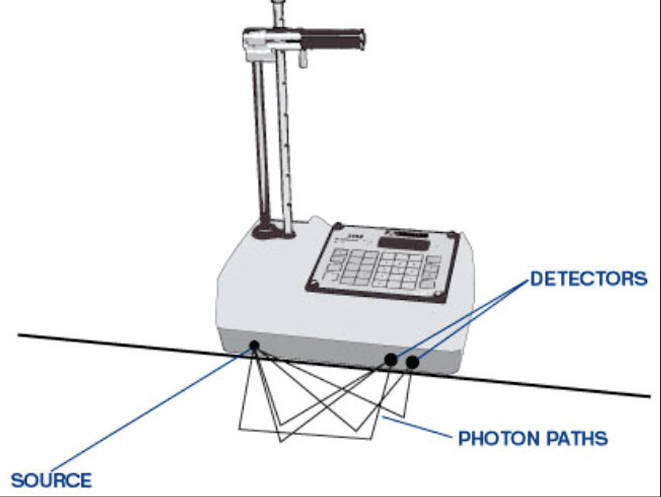

Direct Transmission Measurement

To test the material, the source rod of the gauge is inserted through the base and into a pre-drilled hole up to 12 inches (30 cm) deep. Gamma rays are then transmitted from the density source through the test material and detected by sensors within the gauge.