No Products in the Cart

In the construction industry, achieving reliable results from compression testing of materials like concrete and cement mortar is of utmost importance. This testing process plays a critical role in ensuring the quality and safety of structures. Therefore, it is essential to prioritize the accuracy of these tests as it directly influences the integrity and reliability of the buildings and projects we work on. One brand that stands out in the market is UTEST, with its range of advanced Automatic Compression Testing Machines. Here a some reasons why many professionals prefer UTEST Automatic Compression Testing Machines over other brands in the industry.

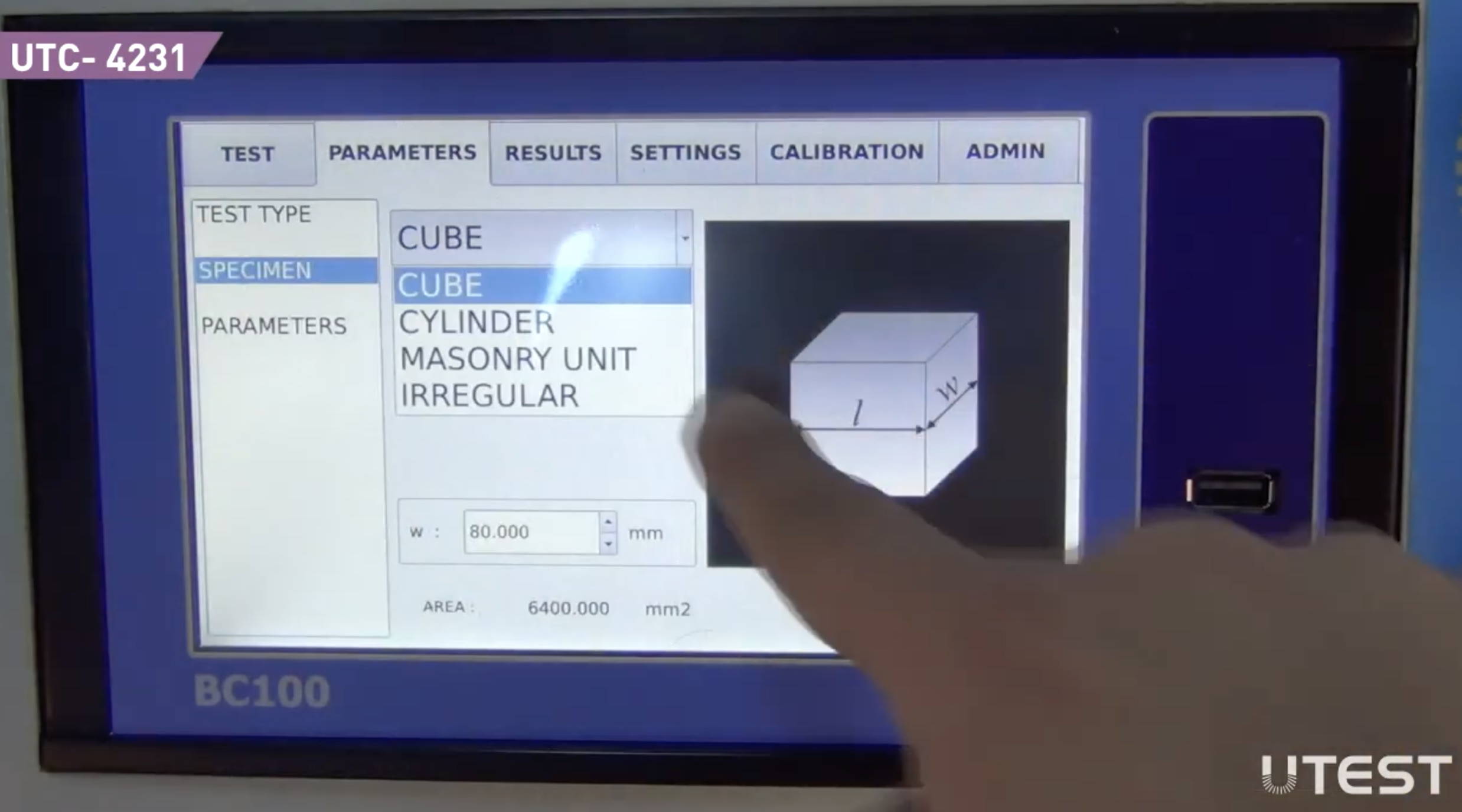

Ease of Use for Inexperienced Operators:

UTEST Automatic Compression Testing Machines are designed to be user-friendly, even for inexperienced operators. Once the machine is switched on and the specimen is properly positioned, the only required operations are setting the test parameters, such as specimen type, dimensions and pace rate (when changing specimen type), and pressing the START button on the control unit. This simplicity allows beginners to conduct tests with accuracy and efficiency, minimizing errors and retesting.

Automated Testing Process:

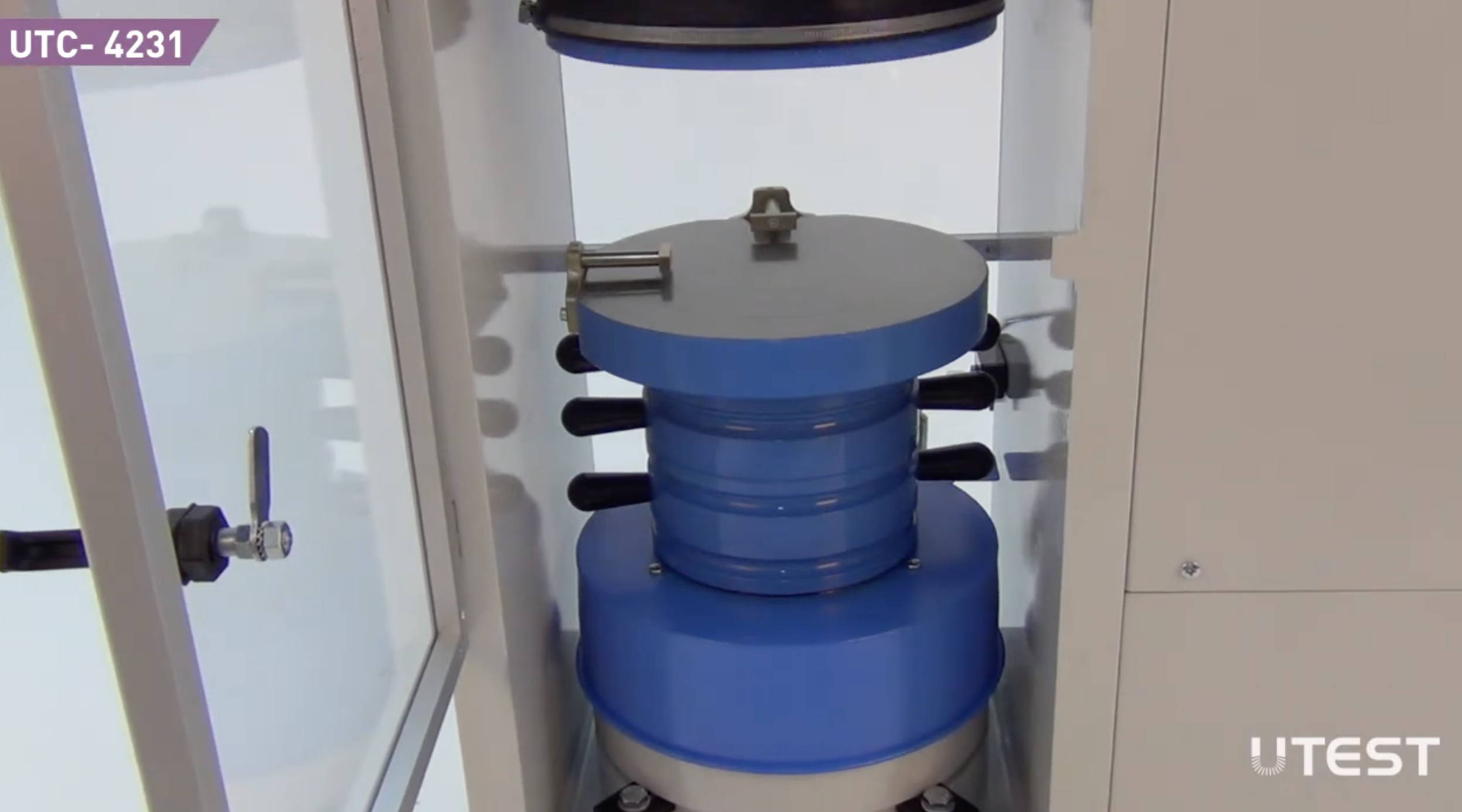

One of the key features that set UTEST machines apart is their ability to perform tests automatically with closed-loop control. The machine initiates a rapid approach until the specimen touches the upper platen, after which it automatically begins loading at the pace rate selected by the user. The test stops as soon as the specimen fails. This automation not only saves time but also ensures consistent and precise test results.

High Accuracy and Reliability:

UTEST Automatic Compression Testing Machines boast high accuracy, with models classified under Accuracy Class A according to E74 starting from 5% of the machine capacity. Moreover, there is an option for special calibration, allowing Class A accuracy starting from as low as 1% of the full range. This level of accuracy makes these machines suitable for conducting tests according to ASTM C39 and AASHTO T22 standards.

Robust Construction and Safety Features:

UTEST prioritizes the safety of operators and the durability of their machines. The machines are constructed with a welded steel frame, providing sturdiness and stability during testing. The inclusion of safety features such as maximum pressure valves, limit switch for piston stroke, and removable transparent safety doors further enhances the overall safety of the testing process.

U-Touch PRO Control Unit:

UTEST U-Touch PRO Control Unit plays a significant role in the seamless operation of the Automatic Compression Testing Machines. The control unit is equipped with an easy-to-use touch screen display, allowing operators to control all the operations efficiently. It also offers real-time graphical displays of "Load vs. Time" and "Stress vs. Time," enabling users to monitor the test progress effectively.

UTEST Software for Enhanced Testing Capabilities:

For even more comprehensive testing capabilities, UTEST provides the UTEST software (USOFT-4830.FPR) to control the Automatic Compression Testing Machines via a computer. This software facilitates advanced reporting, graphical output, and additional functionalities that contribute to a more efficient testing workflow.

These machines are not only capable of meeting and exceeding the requirements of ASTM and AASHTO standards but also offer additional software capabilities for enhanced testing and reporting. Additionally, UTEST Automatic Compression Testing Machines are versatile in various aspects, making them suitable for a wide range of applications and testing scenarios.

Multiple Models and Capacities: UTEST provides a variety of models with different capacities, ranging from 600kN to 3000kN. This wide range of capacities allows users to choose the most appropriate machine based on their specific testing needs. Whether it's small-scale testing for low-capacity materials or heavy-duty testing for high-strength materials, there is a model to accommodate diverse requirements.

Testing Different Materials: These compression testing machines are not limited to testing a single type of material. They are designed to perform compression tests on various construction materials such as concrete, cement mortar, and masonry units/blocks. This versatility is valuable for laboratories and industries that deal with a wide range of construction materials and need a single machine capable of handling multiple testing applications.

Optional Additional Frame: UTEST provides an optional additional testing frame for compression and flexural testing. By incorporating a second testing frame, the machines can provide load control for two separate testing frames independently. This feature extends the versatility of the machines and allows users to perform different types of tests without the need for separate equipment.

Measur is here to assist you and provide the necessary information and support for your concrete testing needs. Have all your inquiries addressed promptly through the form below, telephone, or live chat.