No Products in the Cart

The Los Angeles Abrasion Test aids construction professionals in conducting quality control assessments, allowing them to carefully evaluate and choose the most suitable aggregates tailored to specific projects, ultimately ensuring the longevity and safety of the constructed structures. By scrutinizing abrasion resistance, engineers can make informed predictions about how aggregates will perform in real-world conditions, be it in road surfaces or concrete structures.

Additionally, the test aligns with the requirements of numerous regulatory bodies and standards organizations like ASTM and AASHTO, ensuring that aggregates conform to stringent quality and durability criteria. The judicious selection of aggregates, as facilitated by this test, can lead to substantial cost savings for construction companies, as it minimizes maintenance and repair expenses throughout the project's lifespan.

Here's a step-by-step breakdown of how the test is conducted:

Sample Preparation: A representative sample of the aggregate to be tested is obtained, typically weighing between 5,000 to 10,000 grams. This sample is then washed, dried, and sieved to obtain particles within a specific size range.

Testing Machine: The prepared aggregate sample is placed in the Los Angeles Abrasion testing machine, which consists of a hollow steel drum with a closed end, mounted on a horizontal axis. Inside the drum, a specified number of steel balls or cylpebs are added.

Test Procedure: The drum is rotated at a speed of 30 to 33 revolutions per minute for a predetermined number of revolutions (usually 500 to 1000). During this time, the aggregate inside the drum undergoes repeated impacts and abrasion from the steel balls or cylpebs.

Sieve Analysis: After the specified number of revolutions, the aggregate is removed from the drum, and a sieve analysis is conducted to determine the percentage of material retained on specific sieve sizes.

Calculations: The results are calculated based on the weight loss and the percentage of material passing through various sieve sizes. The Los Angeles Abrasion Value (LAAV) is calculated as a percentage loss of weight.

Interpreting The Results: The Los Angeles Abrasion Value (LAAV) is a crucial parameter obtained from the test. A higher LAAV indicates greater abrasion and fragmentation, which means the aggregate is less resistant to wear and tear. Conversely, a lower LAAV suggests better durability and abrasion resistance.

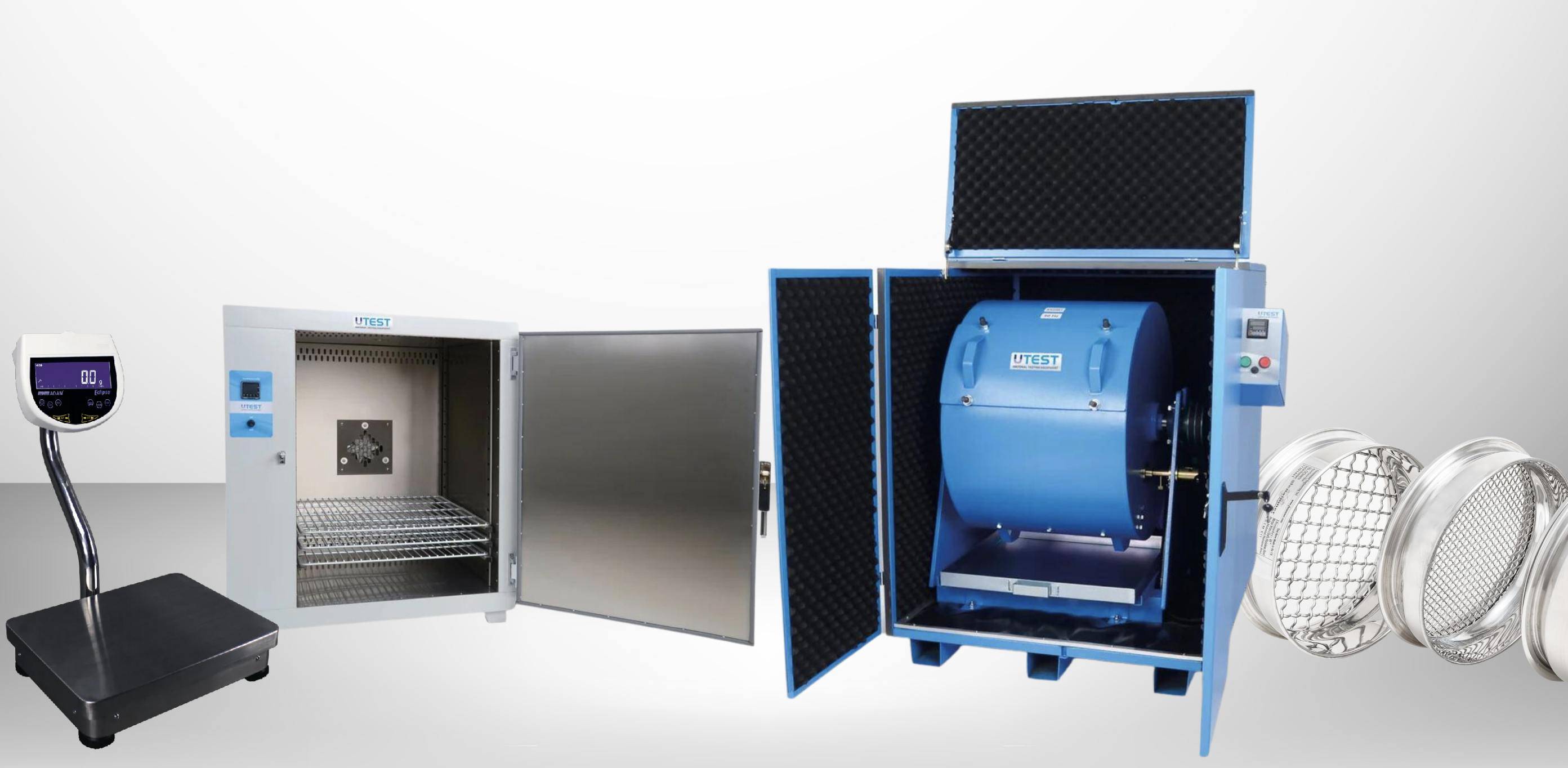

Apart from the Los Angeles Abrasion testing machine, which is the central piece of equipment, several other tools and materials are needed to conduct the test properly. Here's a list of some of the key items:

Balance: A precision balance is required to accurately measure and record the weight of the test samples before and after testing. The balance should have a capacity sufficient to handle the sample size used in the test.

Sieves: A set of sieves is used to prepare the aggregate sample for testing. The sieves are typically made of brass or stainless steel and come in various sizes. They are used to separate the aggregate into different particle sizes and ensure that the sample falls within the specified size range.

Oven: An oven is used to dry the aggregate sample before testing. The aggregate must be completely dry to ensure accurate results. The oven should be capable of maintaining a temperature of 110 ± 5°C (230 ± 9°F).

Cleaning Brush: A soft-bristle brush is used to clean the aggregate particles and the interior of the Los Angeles Abrasion testing machine to remove any loose material that may affect the results.

Steel Balls or Cylinders: Steel balls or cylpebs are placed inside the testing machine's drum along with the aggregate sample. These steel components are used to subject the aggregate to repeated impacts and abrasion, simulating the wear and tear it would experience in real-world applications.

Sieve Shaker: A mechanical sieve shaker can be used to facilitate the sieving process, ensuring that it is consistent and that the aggregate sample is thoroughly separated into different particle sizes.

Calipers or Ruler: These tools are used to measure the dimensions of the steel balls or cylpebs used in the test to ensure they meet the specified standards.

Measur is here to assist you and provide the necessary information and support for your aggregate testing needs. Have all your inquiries addressed promptly through the form below, telephone, or live chat.