No Products in the Cart

The UTEST Automatic Mechanical Compactor is a specialized equipment designed for performing soil compaction tests according to ASTM and AASHTO standards. Soil compaction tests are essential in geotechnical engineering and construction projects to assess the density and strength of soil samples.

The purpose of soil compaction tests is to simulate the effects of compaction equipment, such as rollers and compactors, on soil materials used in construction. By compacting soil samples under controlled conditions, engineers can evaluate the soil's suitability for supporting structures like roads, buildings, embankments, and retaining walls.

Assessing Soil Strength: Compacted soil should exhibit sufficient strength to support applied loads without excessive settlement or deformation.

Determining Optimal Moisture Content: Compaction tests help identify the moisture content at which soil achieves maximum density, known as the optimum moisture content. This parameter is crucial for achieving effective compaction in the field.

Ensuring Uniformity: Compaction tests aim to achieve uniform compaction throughout the soil sample, ensuring consistent density and strength properties across different layers.

Quality Control: Soil compaction tests serve as a quality control measure during construction projects, helping to verify that specified compaction standards are met.

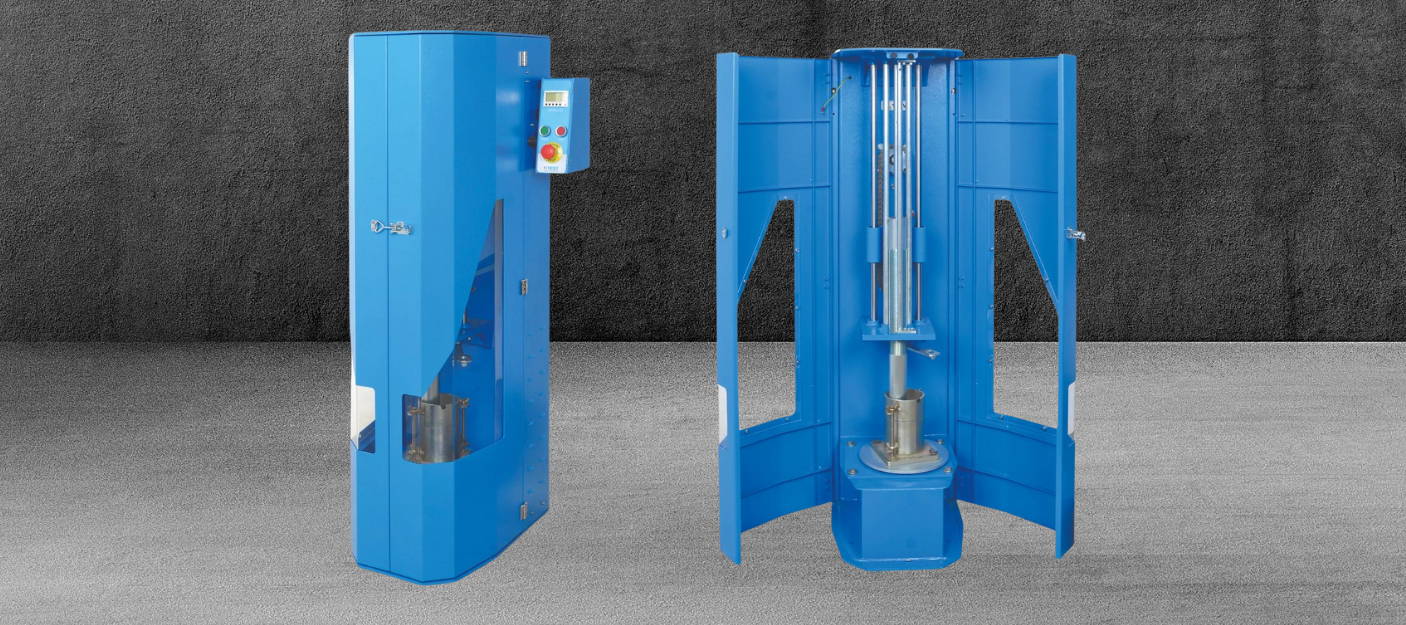

The UTEST Automatic Mechanical Compactor facilitates these tests by providing a controlled environment for compacting soil samples with predefined parameters such as drop height, hammer weight, and number of blows per compaction cycle. It automates the compaction process, ensuring accuracy, repeatability, and adherence to testing standards.

Soil compaction testing is a fundamental procedure in civil engineering and construction projects to ensure the stability and durability of structures built on soil. The UTS-0660 Automatic Mechanical Compactor by UTEST is an innovative solution designed to streamline and automate the soil compaction process while adhering to ASTM and AASHTO standards.

Before proceeding with the soil compaction test, it's crucial to familiarize yourself with the UTEST Automatic Mechanical Compactor and its manual. This equipment is specifically engineered to achieve fast and precise compaction of soil samples. Take note of its key features, including the hammer configurations, mold sizes, and automatic stop mechanism.

Select a representative soil sample and prepare it according to the testing standards specified by ASTM and AASHTO. Ensure the sample is free from debris and uniformly distributed within the compaction mold. Choose the appropriate mold size (4” or 6” diameter) based on the testing requirements.

Choose the hammer configuration suitable for your compaction test. For standard compaction tests, use the 5.5 lb. circular-faced hammer with a 12” drop height. For modified compaction tests, opt for the 10 lb. pie-shaped hammer with an 18” drop height. Adjust the compactor settings to accommodate the chosen hammer and mold size.

Configure the compactor to meet the desired compaction parameters, such as the number of blows per compaction cycle. The machine is equipped with an automatic stop feature, ensuring consistent compaction results by halting the operation after the preset number of blows is completed.

With the soil sample properly prepared and the compactor settings adjusted, initiate the compaction process. The UTEST Automatic Mechanical Compactor will automatically perform the specified number of blows per cycle, compacting the soil sample to the required standards.

Throughout the compaction process, closely monitor the compactor's operation to ensure smooth functionality. Pay attention to the indexing of the circular base with each blow, ensuring uniform sample compaction. The pie-shaped compactor foot should completely cover the surface of the sample for effective compaction.

To conduct a soil compaction test alongside the UTEST Automatic Mechanical Compactor, engineers and technicians require a range of essential tools and equipment. These include soil sampling tools like hand augers or probes, various compaction molds compliant with ASTM and AASHTO standards, a balance or scale for measuring sample weight, a drying oven for moisture content determination, and a soil moisture meter for on-site readings. Additionally, gradation testing equipment such as sieves and a sieve shaker may be necessary, along with tools for additional compaction tests like the Proctor test or CBR test.

Give us a call or drop by anytime, we will answer all enquiries within 24 hours on business days. We will be happy to answer your questions.

We would love to hear from you! Our team is always here to help.

+1 866 300 9012

contact@measur.ca

Vancouver, British Columbia

Calgary, Alberta

Mississauga, Ontario

Montreal, Quebec