No Products in the Cart

As a commonly used material in the construction of roads, highways, and parking lots, asphalt must meet certain standards to ensure its longevity and safety, hence the importance of performing asphalt tests. The Marshall test, also known as the Marshall Stability test, is a common method for determining the strength and stability of asphalt mixtures. The test involves compacting a cylindrical sample of the mixture at a specific temperature and then loading it with a controlled force. The sample is then examined for various properties such as density, air voids, and stability.

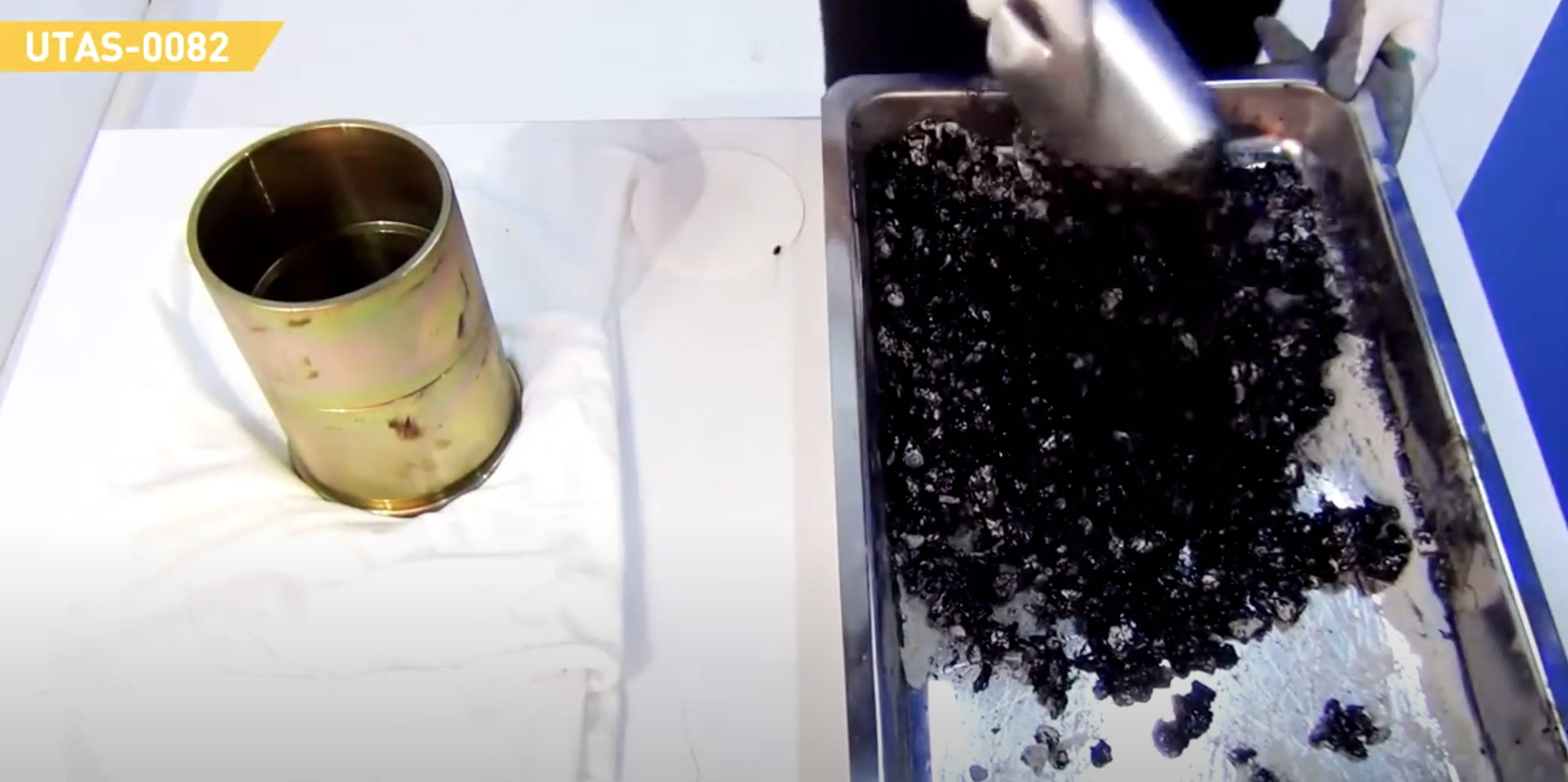

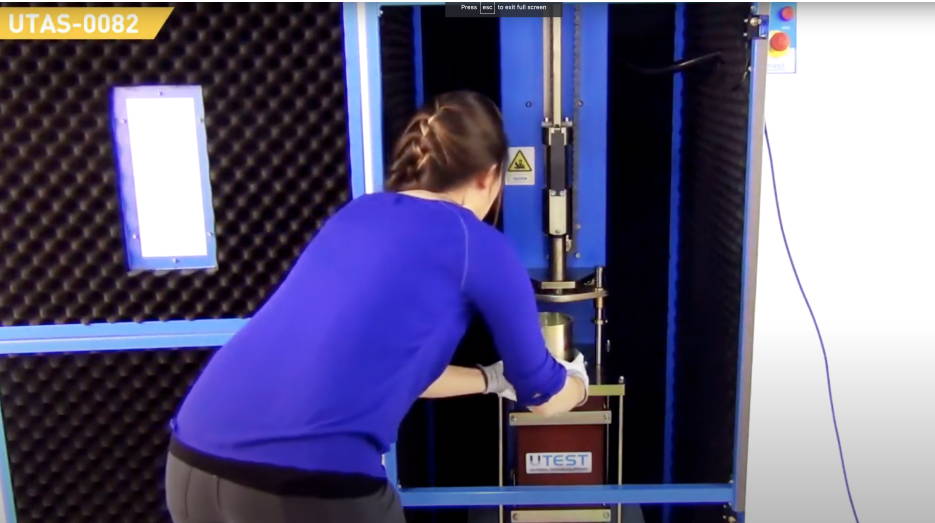

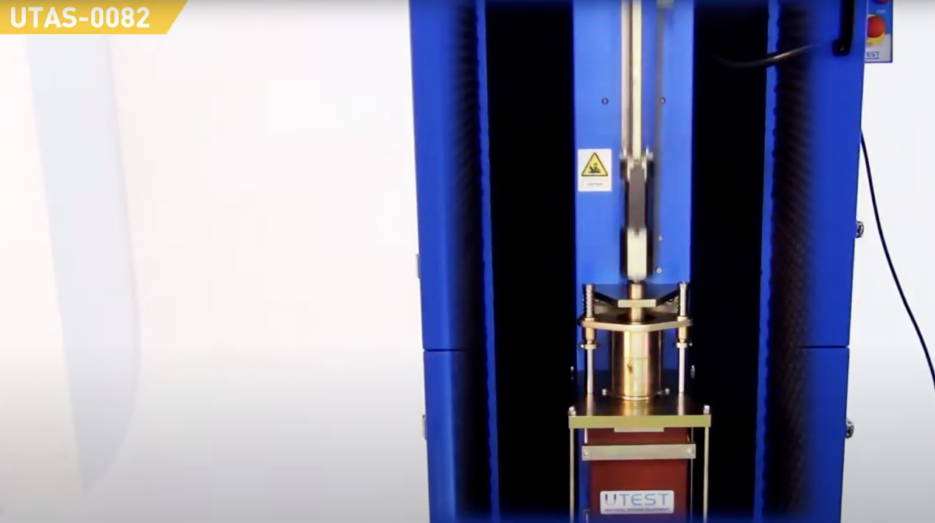

1. Sample preparation: A cylindrical sample of the asphalt mixture is prepared using a 4 or 6 inch Marshall Mold. The asphalt sample is placed in the mold and compacted with a Marshall compactor, which is dropped from a specific height, usually 12 inches. The number of hammer blows should also be consistent, typically around 50.

2. Heating: The sample is then heated to a specified temperature, typically between 150 and 170 degrees Celsius, using a laboratory oven or hot water bath. The heating should be done in a controlled manner to ensure that the sample is heated evenly and to the specified temperature.

3. Compaction: After heating, the sample is compacted again with the compactor, this time with a specified number of blows, typically around 75. This is done to find specific density and air void content in the sample.

4. Measurement: Once the sample is compacted, the density, air voids, and stability of the sample are measured using a density gauge. The Marshall stability and flow values are then calculated using specific formulas, which are based on the density, air voids, and stability of the sample.

5. Comparison: The results of the test are then compared to the specifications for the desired asphalt mixture to determine if the mixture is suitable for use. The Marshall stability and flow values should fall within the specified range for the mixture. The air voids content should also be within a specified range, typically between 4 and 8%.

REMEMBER: It is important to always follow the regional standards for any test along with the manufacturer's instructions. All information posted by Measur is for informational purposes only and may or may not meet the required standards in your geographical location.

For more detailed information about the test please visit the following sources:

ASTM D6927-22 Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures