No Products in the Cart

Concrete is the backbone of construction, and ensuring its strength is non-negotiable. Grinding machines for concrete testing are indispensable tools that contribute to the safety and reliability of buildings, bridges, and infrastructure projects. Concrete specimens used for testing need to have flat and parallel surfaces and this is where these machines shine.

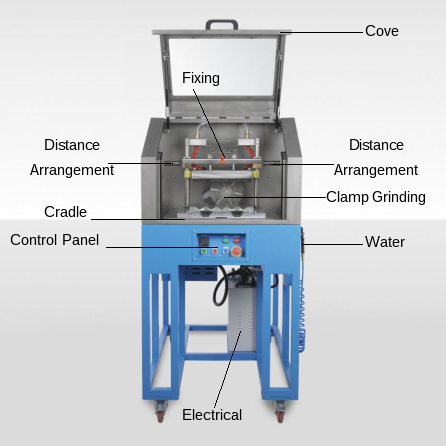

Automatic Grinding Machines are key players in meeting ASTM standards. They ensure that the planeness of grinded surfaces is as low as 0.05mm, while maintaining a deviation of perpendicularity within 0.5°. Here we look at these two industry-leading options: the Automatic Grinding Machine and the Automatic Grinding Machine with Cabinet.

This machine is designed to provide fast grinding of cylinder specimen ends to achieve plane and parallel surfaces, in line with EN and ASTM standards.

It's equipped with numerous features that make it a versatile and essential tool for concrete testing laboratories.

Key Features and Specifications:

Capacity: Simultaneously grinds three units of Ø38 to 100 mm concrete cylinder ends or two units of Ø150-160 mm concrete cylinder ends. Also, it can handle three units of 100 mm or one unit of 150 mm concrete cube faces.

Grinding Time: The user can adjust grinding times from 50 to 400 seconds, with an optimum grinding time per end of 90 to 120 seconds.

Precision: Meets strict planeness accuracy and perpendicularity standards of 0.05 mm and 0.5°, respectively.

Convenience: Ergonomic design helps keep employees safe, and the wheels ensure easy mobility.

Durability: Aluminum frame for lightweight construction and stainless steel exterior shell for corrosion resistance.

Additional Components: Water restraint panel set and optional water tank with filtration and circulation system.

For those seeking a larger grinding capacity, and cleaner, quieter workspace, the Automatic Grinding Machine with Cabinet is a compelling choice.

This model is equipped to handle a wider range of specimen sizes and types while the cabinet reduces noise, water and dust in your workspace.

Key Features and Specifications:

Enhanced Capacity: Can grind up to five units of Ø38 to 50 mm cylinder ends, three units of Ø70 to 110 mm cylinder ends, two units of Ø110 to 160 mm cylinder ends, three units of 100 mm cube faces, and one unit of 150 mm cube face.

Same Precision and Features: Offers the same selectable advance grinding time, bidirectional radial displacement, ergonomic design, and mobility with integral wheels.

Cabinet Convenience: The cabinet helps keep unwanted dust, water and noise from entering your work area. A convenient water spray gun is also included for easy maintenance.

Durability: Like the standard model, the machine boasts stainless steel parts for durability and corrosion resistance.

Additional Components: The option to include a filtration and circulation system water tank and a cradle for 100mm or 150mm cube specimens.

Measur is here to assist you and provide the necessary information and support for your concrete testing needs. Have all your inquiries addressed promptly through the form below, telephone, or live chat.