No Products in the Cart

Concrete may seem like a humble building material, often overlooked in our busy lives. But the truth is, it's the hero of the modern world, providing the sturdy foundations for our homes, the bridges we drive across, and the skyscrapers that touch the sky. Behind this substance lies a world of precision, where quality is of the highest importance. In this blog, we explore 5 essential tests that ensure concrete meets the highest standards.

Compressive strength is a critical property of concrete, as it determines its ability to withstand loads and pressures. The compressive strength test involves casting concrete cylinders or cubes, curing them under specific conditions, and then subjecting them to a compressive load until they fail.

The maximum load the sample can bear before failure is recorded, and it serves as an indicator of concrete's structural performance. Engineers use this test to verify if the concrete has reached its specified strength for construction purposes.

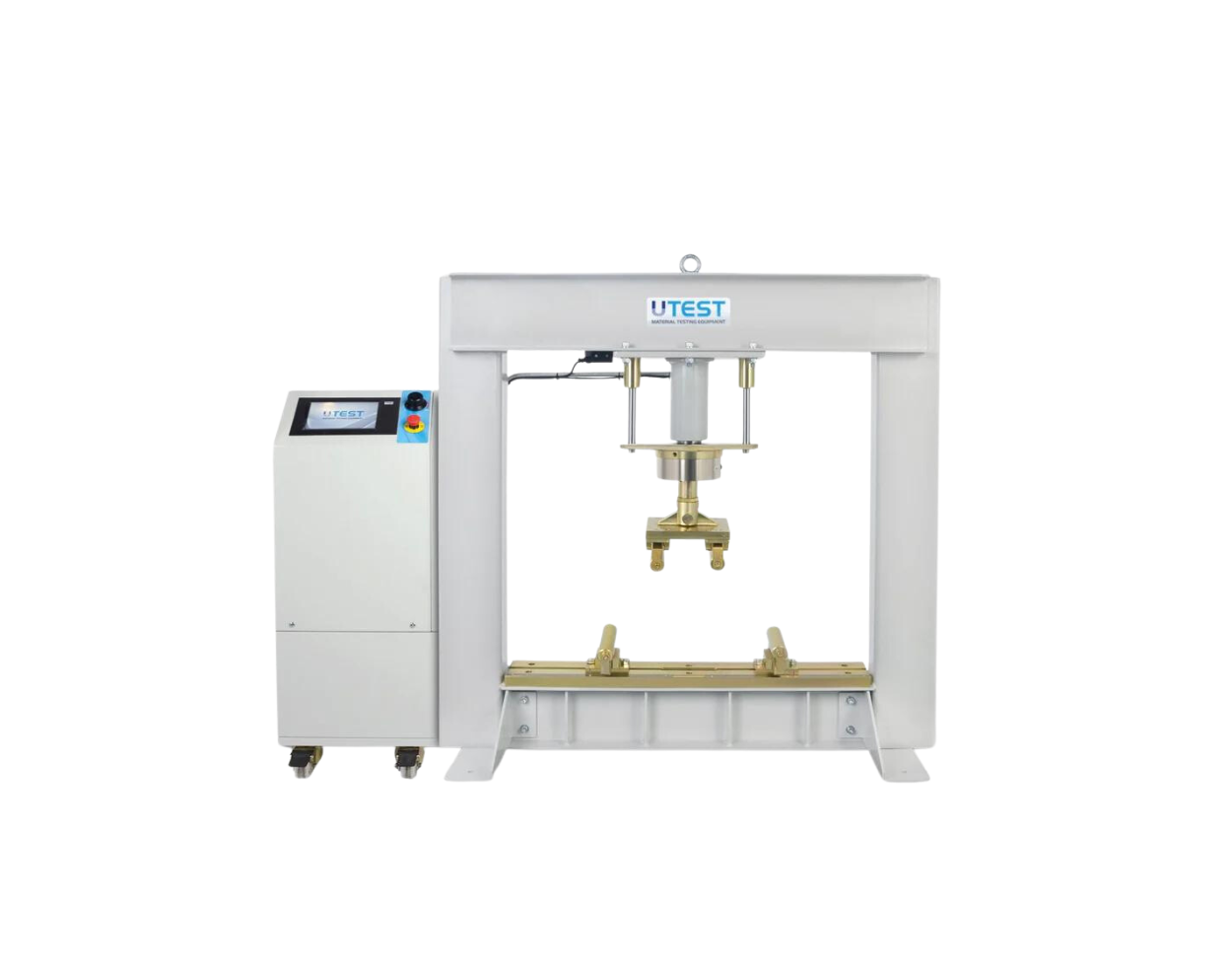

The Flexural Strength Test measures a concrete's ability to resist bending or cracking under load. This test is particularly important for applications like beams and slabs. A sample beam is subjected to a bending load, and the stress and strain on the beam are recorded.

Flexural strength testing helps ensure that concrete components can safely distribute loads without failure.

The Slump Test is a simple and widely used test to evaluate the workability of freshly mixed concrete. Workability refers to the ease with which concrete can be mixed, placed, and compacted without segregation or excessive bleeding.

In this test, a cone-shaped mold is filled with concrete, and the cone is then removed, allowing the concrete to settle. The difference in height between the original cone and the settled concrete is measured, indicating the concrete's workability. Proper workability ensures that concrete can be placed and finished without complications.

The Air Content Test, conducted using an air meter, is crucial in construction to assess the amount of air trapped within concrete or mortar mixtures. This information helps ensure the material's durability and performance. An air meter is used to directly measure the volume of air in the sample by subjecting it to a vacuum.

The difference in volume before and after the air is removed provides the air content percentage, which is crucial for quality control. This test ensures that construction materials meet specified standards, contributing to the longevity and safety of structures.

The Rapid Chloride Permeability Test is essential to predict the susceptibility of concrete to chloride ion penetration, which is a leading cause of concrete deterioration, particularly in coastal and de-icing salt-exposed environments.

The test involves subjecting a concrete specimen to an electrical current while it is submerged in a chloride solution. Chloride ions migrate through the concrete under this electrical field, simulating real-world conditions. By measuring the rate of chloride ion penetration and the amount that penetrates the concrete, engineers can assess its resistance to chloride-induced corrosion.

A low RCPT result indicates that the concrete has a high resistance to chloride penetration and is likely to have a longer service life. This information is vital for designing durable and long-lasting concrete structures.

By conducting these tests, engineers and builders can make informed decisions, select appropriate mix designs, and ensure that the concrete used in construction meets the required standards, ultimately leading to safer and more reliable structures.

Measur is here to assist you and provide the necessary information and support for your concrete testing needs. Have all your inquiries addressed promptly through the form below, telephone, or live chat.